Today, Wuxi Rizhuan Sensing Technology Co., Ltd. will introduce a new solution for 3C mobile phone material tray inspection: the practical application of Rihuan Sensing's REZ series ultra-thin photoelectric sensors.

A leading 3C mobile phone manufacturing enterprise in China is facing a core requirement for material tray positioning detection on its automated production line. The material trays on the production line carry various precision core components such as mobile phone chips and display screens. They must be accurately transferred to the preset positions to ensure the smooth operation of subsequent mechanical arm grasping and assembly processes. Any deviation in material tray positioning can not only cause interruptions in the production process but also lead to problems such as damaged components and substandard product quality.

Installation space limitation: Traditional sensors are relatively large in size and difficult to fit into the narrow installation area of the tray track;

High response efficiency requirements: The production line operates at high speed, and sensors need to complete the detection within milliseconds and provide feedback signals in sync with the production rhythm;

Environmental adaptability requirements: In complex production scenarios, it is necessary to ensure that the detection signals are not disturbed and output stably.

Customized solution

After multi-dimensional technical assessment and scenario adaptation testing, the company ultimately recommended the REZ series of independent ultra-thin photoelectric sensors from Dayhuan Sensing to the client. This product, with its ultra-thin design of 5mm, extremely high detection accuracy and fast response capability, successfully solved the dual problems of space and performance in the production line.

Product Core Highlights

Ultra-thin structure, flexible installation: The REZ series of independent ultra-thin photoelectric sensors have a thickness of only 5mm. They can be easily embedded in the limited space on the side or top of the material tray track, without the need to modify the existing production equipment structure. Installation is convenient and efficient, and it will not interfere with the normal flow of materials.

High precision detection, precise positioning: This sensor can stably identify opaque objects larger than Φ4mm. By sensing changes in light signals, it can accurately determine whether the material tray has reached the designated position, eliminating the risk of positioning errors.

High-speed response, compatible with production rhythm: The response speed of the sensor can reach 1ms. It can quickly complete the detection and output signals, synchronizing perfectly with the high-speed operation of the robotic arm and the production line rhythm, effectively avoiding production delays and helping to improve overall production efficiency.

Strong anti-interference, stable operation: The REZ series sensors have excellent anti-complex environmental interference performance. Even in harsh production environments, they can maintain the reliability and continuity of the detection signals, ensuring the smooth progress of the production process.

Project Implementation Results

By deploying the REZ series ultra-thin photoelectric sensors from Dayuan Sensing on the production line, the customer achieved precise detection and real-time monitoring of the material tray movement, achieving multiple benefits:

✅ Significant improvement in production efficiency: The detection of the material tray's correct placement has achieved zero errors, and the success rate of the robotic arm's grasping has been greatly enhanced;

✅ The product quality has been continuously improved: Completely avoided the problems of component damage and assembly errors caused by positioning deviations;

✅ Effective reduction of operation and maintenance costs: The sensor has strong anti-interference capability and high long-term operational stability, significantly reducing downtime due to faults and maintenance costs.

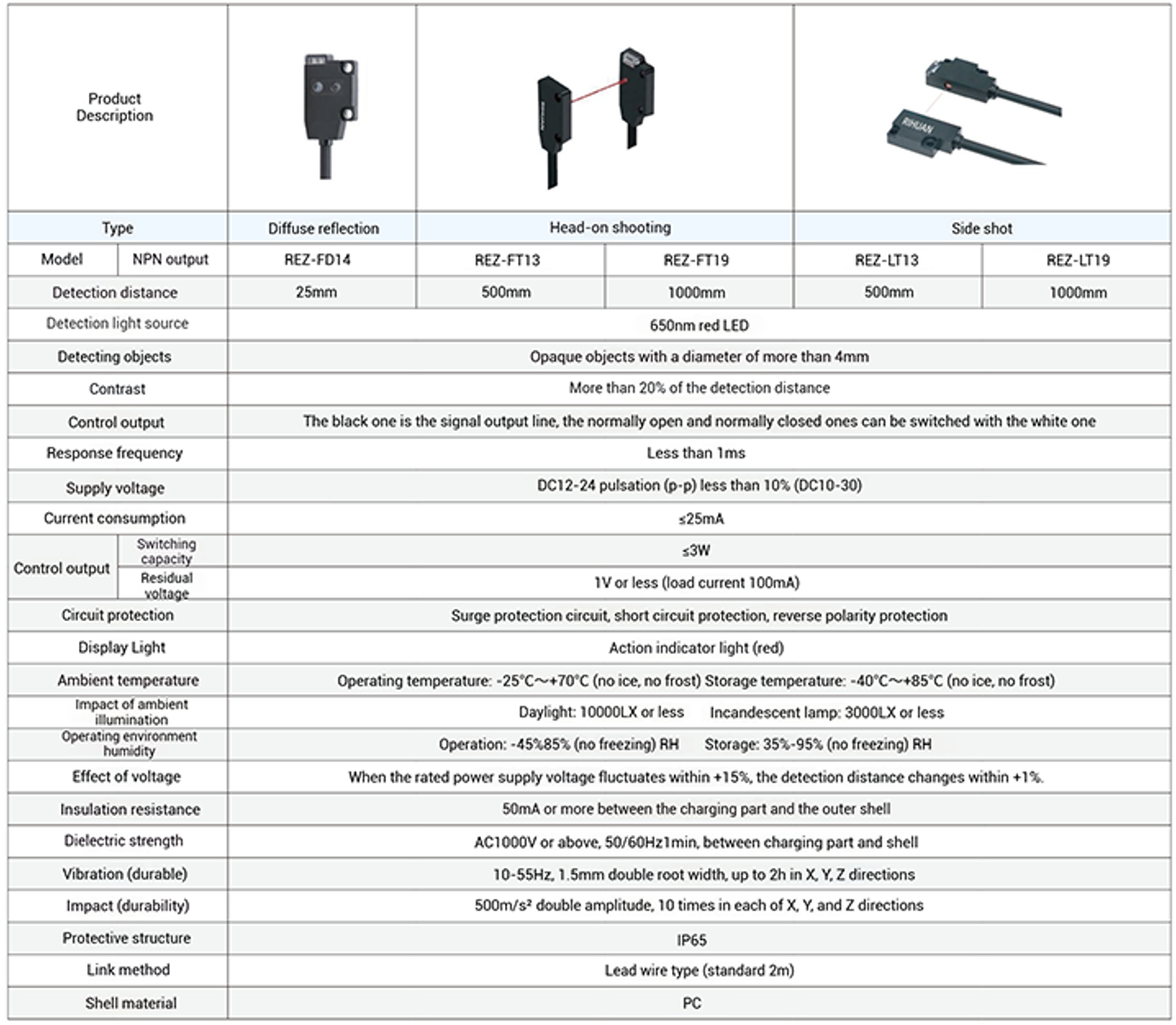

Product detailed parameters