Today, Wuxi Rihuan Sensing Technology Co., Ltd. will introduce a new compliance testing solution for bottle cap gaskets: The Rihuan Sensing REB-W500 series long-distance color sensor provides precise empowerment.

A leading enterprise in the packaging industry has a specialized bottle cap production line. In the product manufacturing process, the proper installation of the internal gasket in the bottle cap is a crucial step for ensuring the sealing performance and usage quality of the product. To accurately identify and eliminate the defective bottle caps (those with missing gaskets or incorrect installation of the gasket) on the production line, this enterprise urgently needs a high-performance sensor to automatically and precisely determine the assembly status of the gasket, thereby ensuring the consistency and sealing reliability of the factory-produced bottle caps.

Core challenges in detection

Difficulty in distinguishing colors: Qualified gaskets are pure silver in color, while unqualified scenarios include no gaskets and gaskets with red markings. Most sensors on the market struggle to accurately distinguish the subtle color differences between silver and the red markings.

High response requirements: The production line operates at a high speed, and the sensors must complete the detection within milliseconds and output feedback signals to ensure synchronization with the production rhythm.

Installation conditions are restricted: The distance between the sensor installation position and the detection target should be no less than 400mm. This clearly sets requirements for the long-distance detection capability of the equipment.

Customized solution

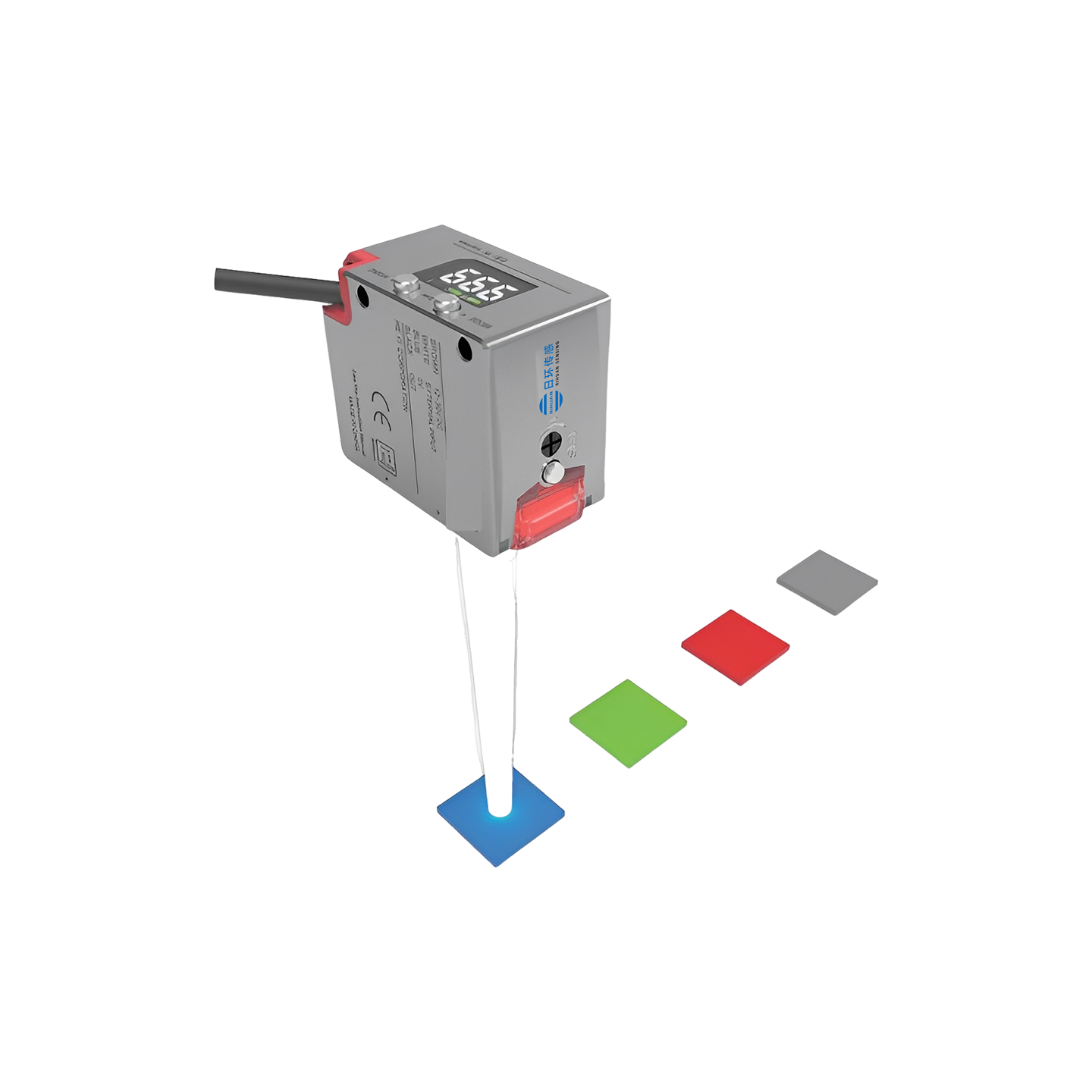

After a comprehensive analysis of the working conditions and technical assessment, Rihuan Sensing has recommended the REB-W500 series of white LED light source long-distance color sensor for customers. With its outstanding color recognition accuracy and fast response characteristics, it has built a fully automatic sorting system for bottle cap gasket compliance. The core advantages are as follows:

Long-distance precise color recognition: The detection range covers 50mm - 500mm, perfectly matching the 400mm installation requirements. The light spot is highly focused, and it has excellent resistance to environmental light interference, which can accurately capture the color differences between silver and red markings;

Stable detection without worries: Using a wide-wavelength white LED light source, it achieves high-precision color differentiation. At the same time, it integrates anti-shake design and background suppression technology, effectively avoiding external interference factors, ensuring the stability of the detection results;

High-speed response compatibility: The millisecond response speed is highly matched with the production line's rhythm, ensuring that the detection action does not affect the normal operation of the production line.

Implementation and deployment: Install the REB-W500 series sensors above the conveyor belt (installation distance ≥ 400mm). When a pure silver-colored qualified gasket is detected, the system releases the product; if a gasket with a red marking or an unqualified product without a gasket is identified, the air blowing device is triggered immediately to complete the automatic rejection. The entire process does not require manual intervention, achieving full-process automated detection and sorting.

Product Core Highlights

White LED wide wavelength light source design enables stable identification of various color differences and appearance flaws;

Excellent anti-shake performance, combined with background suppression function, significantly improves detection stability;

Supports long-distance detection scenarios, suitable for complex installation conditions;

Can simultaneously store 9 sets of color reference samples, meeting the detection requirements of multiple scenarios;

Optional IO-LINK communication function, facilitating equipment networking and data transmission;

Light spot can be modulated as needed, adapting to different detection target sizes.

Application Implementation Results

By introducing the REB-W500 series long-distance color sensor from Day Ring Sensing, the customer's bottle cap production line achieved automated and high-precision pad compliance detection, with remarkable results:

✅ Quality Control Upgrade: The occurrence rate of quality issues such as pad omission and reverse installation has significantly decreased, the compliance rate of bottle cap sealing performance has significantly improved, and the product quality stability has been effectively guaranteed;

✅ Production Efficiency Optimization: The detection and rejection actions are seamlessly integrated with the production rhythm, the production line speed has further improved, completely eliminating the need for manual re-inspection, and the production process has become more efficient;

✅ Comprehensive Cost Reduction: The sensor has strong long-term operational stability, with low maintenance frequency, effectively reducing equipment downtime losses, while saving labor costs, creating higher economic benefits for the enterprise.

Product Detailed Parameters

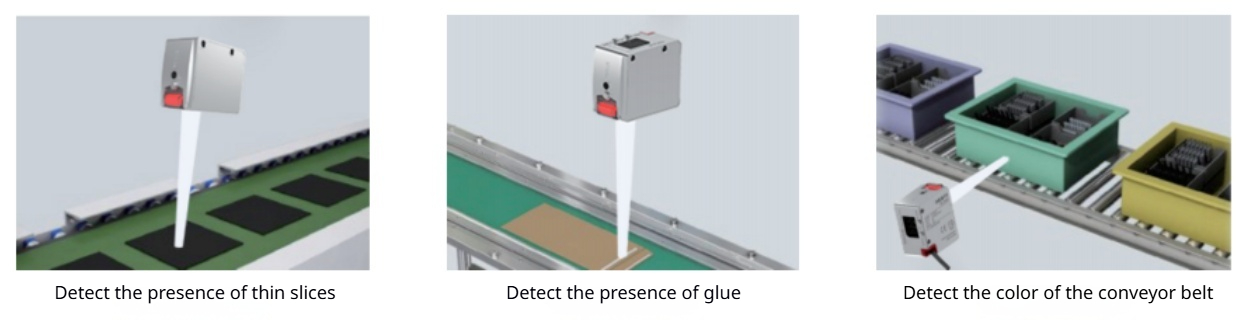

Typical application scenarios