The following will elaborate on the core information of laser distance sensors from five dimensions: core positioning, working principle, key components, classification methods, and practical applications, point by point.

I. Core Positioning

It is a key device in modern precision measurement technology. With the precise and efficient characteristics of lasers, it has become an important support for promoting technological upgrades in multiple industries.

It is widely applied in fields such as driverless technology, environmental monitoring, industrial manufacturing, and surveying and mapping, and is an indispensable measuring tool in the modern technological system.

Ii. Core Working Principle (Taking Time-of-Flight (ToF) as an Example)

Transmission signal: The laser inside the sensor emits high-energy-density laser pulses, which propagate towards the target object.

Reflection reception: After the laser pulse comes into contact with the target object, it is reflected. The reflected signal is captured by the highly sensitive receiver inside the sensor (such as an avalanche photodiode).

Calculation and processing: The signal processing circuit calculates the time difference between the laser's "emission and reflection", and combines the speed of light to calculate the distance between the sensor and the target.

Result presentation: The final measurement data is visually displayed on the screen for users to read and use.

Iii. Key Components and Their Functions

Laser: As a "signal transmitter", the energy density of its laser pulse directly determines the measurement range and fundamental accuracy.

Receiver: Acting as a "signal catcher", its high sensitivity ensures that weak reflected signals are not missed.

Signal processing circuit: It is equivalent to the "brain" of the sensor, responsible for quickly processing signals and accurately calculating distance data.

Display screen: As an "information transmitter", it transforms complex data into concise and intuitive results that are easy to understand.

Iv. Main Classification Methods

1. Classified by measurement principle

Pulse type: It excels in long-distance and high-precision measurement and is suitable for scenarios such as mapping and military reconnaissance.

Phase type: It stands out for its precision in medium and short distance measurements and is often used for part size inspection in industrial manufacturing.

Interferometric type: By utilizing the laser interference phenomenon and measuring distance through the variation of interference fringes, it is suitable for high-precision demand fields such as scientific research

2. Classified by laser type

Solid-state lasers: Featuring high energy and high stability, they are suitable for scenarios with high requirements for measurement performance.

Gas lasers: With diverse output wavelengths, the appropriate type can be selected according to different measurement environments.

Liquid laser: With stable energy output, it is applied in some special industrial measurements.

Semiconductor lasers: Small in size and low in power consumption, they are suitable for integration into small devices or portable measuring tools.

V. Typical Practical Application Scenarios

Driverless technology: As the "eyes" of the vehicle, it measures the distance and position of surrounding obstacles in real time to ensure driving safety and navigation accuracy.

Environmental monitoring: Accurately measure the diffusion range of air pollutants to assist researchers in analyzing the transmission patterns of pollutants.

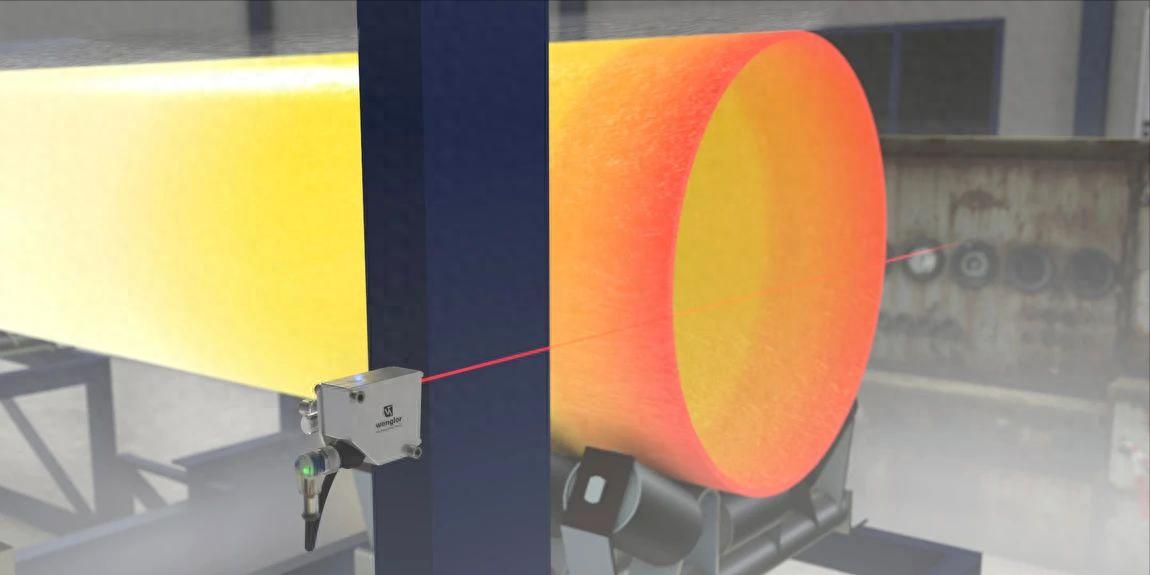

Industrial manufacturing: It is used for calibrating the dimensions of parts on production lines and detecting assembly clearances to ensure that product quality meets standards.

Surveying and mapping exploration: In topographic surveying and construction project layout, it provides high-precision distance data to enhance the accuracy of engineering construction.