Today, Wuxi Rihuan Sensor Technology Co., Ltd. will introduce the causes and solutions of the jitter problem of safety grating.

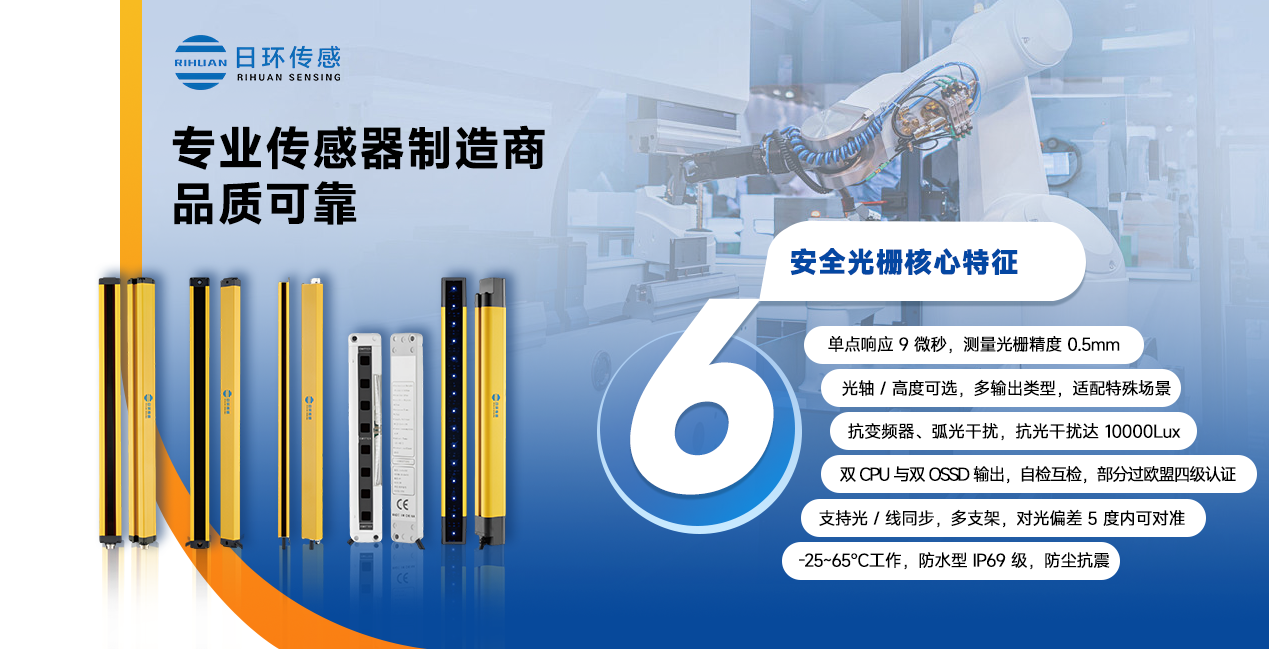

The Rihuan sensor safety barrier, as an indispensable safety protection device in industrial production, can precisely detect the intrusion of people or objects and promptly trigger the machine to stop or halt its operation, thus building a defense line for the safety of on-site workers. However, in actual industrial application scenarios, this device occasionally experiences jittering, which not only easily causes meaningless equipment shutdown but also leads to false detection problems, seriously affecting production efficiency and the normal protective function of the equipment. This article will deeply analyze the common causes of jittering in the circular sensor safety barrier and provide targeted and practical solutions.

I. Core Causes of Jittering in Safety Barrier

The jittering of the circular sensor safety barrier is not caused by a single factor, but is the result of the combined effect of various working conditions and the equipment itself. The most common reasons can be mainly divided into four categories:

Installation position deviation: When the installation position of the barrier does not conform to the specifications, it will directly cause errors in the transmission of the light beam, and the projection of the light spot will become extremely uneven, ultimately causing the detection signal of the equipment to lose stability and triggering jittering.

External environmental interference: The complex environment of the industrial site is an important source of interference for the grating signal. Electromagnetic radiation, vibrations generated by equipment operation, as well as strong light, stray light and other light sources, all can cause interference to the normal signal transmission of the grating, thereby leading to jitter.

Equipment aging or damage: Long-term continuous industrial use will cause the grating to undergo natural aging. In addition, factors such as knocks and dust erosion in the field may also lead to damage to the equipment components. This is also an important internal cause of grating jitter.

Mechanical compatibility issue: If the installation process of the grating does not meet the standards, or if the related components of the industrial machine used for compatibility malfunction or become loose, it will affect the stability of the grating at the mechanical level, ultimately resulting in equipment jitter.

II. Practical Solutions for Addressing Grating Jitter

In response to the various causes of grating jitter, corresponding measures need to be taken to eliminate the problem at its root and restore the stable detection and protection functions of the equipment:

(1) Re-calibrate the installation position of the grating

For jitter caused by positional deviations, the core is to re-calibrate the installation position of the grating. Operators can adjust the beam adjuster or rotate the reflective mirror of the grating to correct the beam transmission error and solve the problem of uneven light spots. After calibration, repeated testing is required to ensure that the grating can stably capture the detection target and avoid jitter and false detection caused by positional issues from the source.

(2) Completely avoid external environmental interference

Interference factors in industrial sites need to be avoided through multiple measures. Specific approaches can be taken from four aspects:

Avoid areas with frequent vibrations and significant temperature fluctuations and re-plan the installation position of the grating;

Replace the cables with those with excellent shielding performance and ensure proper grounding according to standards to resist electromagnetic interference.

Stay away from the strong and miscellaneous light sources in the workshop, and reduce the influence of light on the grating detection.

Use easily cleanable protective materials to cover the photoelectric probe. Regularly clean the dust and oil stains on the equipment surface to ensure the smoothness of the detection light path.

(3) Timely detect and replace faulty equipment

If the grating jitter is caused by its own aging or damage, professional testing and diagnostic tools should be used to conduct a comprehensive inspection of the core components such as the emission end, receiving end, and signal transmission module of the grating. If the components are found to be faulty or the equipment is aged and cannot be repaired, the damaged components or the entire grating equipment should be replaced in time to avoid the failure of protection due to equipment issues.

(4) Completely solve the mechanical problems

When mechanical factors cause grating jitter, a comprehensive investigation of the installation structure of the grating and the supporting machinery should be conducted. If the installation is loose, it needs to be re-regularized and fixed properly; if the relevant components of the supporting machinery malfunction, they need to be repaired or replaced with faulty parts to restore the stability of the mechanical system and indirectly ensure the normal operation of the grating.

Summary

The solar ring sensing safety grating is an important guarantee for the safety of personnel in industrial production sites. The stability of its operation directly relates to production safety and efficiency. When equipment has jitter problems, workers should not handle them blindly. They should first combine the on-site conditions to investigate one by one the reasons in aspects such as installation, environment, equipment itself, and mechanical support, and then take targeted measures such as calibration, anti-interference, maintenance and replacement, and mechanical maintenance.

In daily production, it is also necessary to do regular configuration, standardized installation, and regular maintenance of the grating, and promptly detect potential problems to ensure that the solar ring sensing safety grating always maintains a stable and reliable operation state, fully exerting its safety protection function, and safeguarding industrial production.