Today, Wuxi Rihuan Sensing Technology Co., Ltd. will introduce the Rihuan Sensing solution: building a safety and efficiency barrier for the entire food manufacturing chain.

Food manufacturing is a complex path that carries the safety expectations of millions of consumers and the taste preferences of their palates. From raw material procurement to product delivery, this chain is intertwined with multiple challenges: drastic fluctuations in ingredient costs, increasingly stringent regulatory requirements, high energy consumption, a growing shortage of skilled workers, and even minor losses at each stage can directly affect the profits of the enterprise. In today's industry where safety, efficiency, and sustainability are the core demands, opening up channels for improving the efficiency of the entire chain is no longer an optional optimization option for enterprises; it is a must-answer question related to survival and long-term development.

Rihuan Sensing has been deeply engaged in the field of sensing technology and automation. Leveraging its profound industry experience, it integrates advanced technologies into the core scenarios of food production, becoming the "wise eye" and "sensitive hand" that safeguard this precise chain. Our solutions focus on the key nodes throughout the production process, accurately capturing each set of core data, enabling data-driven intelligent decision-making, and laying a solid foundation for food enterprises to build a safer, more efficient, and more cost-competitive supply chain system.

Raw material processing and storage: Ensuring safety and efficiency from the source

Raw material management is the first line of defense in food production, but it faces many challenges: Inaccurate monitoring of tank levels can lead to spillage waste or pump damage; foreign objects such as metal and stones mixed into the raw materials may cause equipment failures and pose hidden risks to food safety; blockages or interruptions in the raw material transportation process can directly disrupt the production rhythm.

To address these issues, Dayuan Sensing has provided an accurate solution:

Level sensors: Real-time and precise monitoring of liquid raw materials such as syrup and edible oil in tanks, as well as solid raw materials such as grain powder, can not only avoid spillage waste and pump damage, but also achieve refined management of inventory.

Capacitive sensor: Excellent at detecting non-metallic foreign objects such as plastics, woods, and glass fragments. It is also suitable for monitoring the level of non-conductive materials and can promptly detect pipeline blockages, ensuring the purity of raw materials and smooth transportation.

Ultrasonic sensor: It adopts a non-contact measurement method and is not affected by dust. It can accurately detect the level of bulk solid raw materials such as flour and sugar, or determine whether there is any material in the silo, providing a reliable basis for raw material replenishment.

Filling and Sealing: Millimeter-level Precision Ensures Product Quality

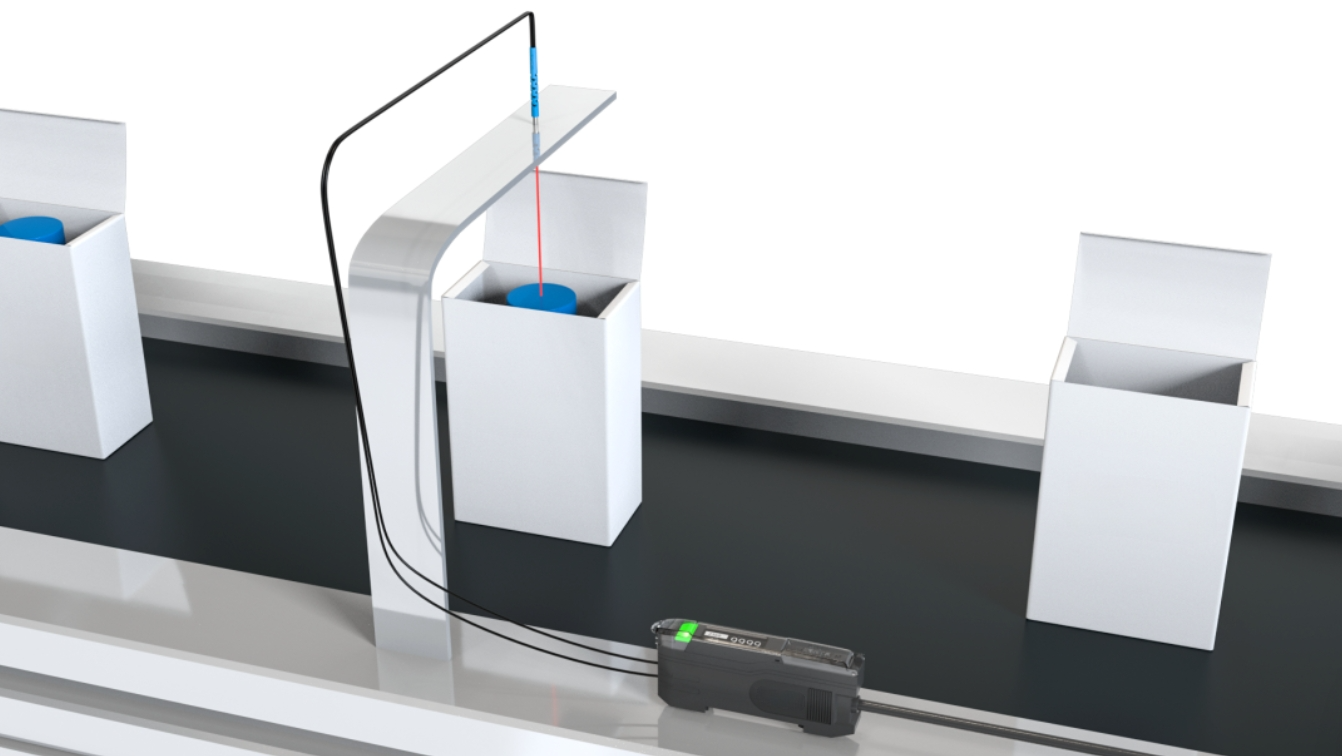

Optical Fiber Amplifier + Fiber Combination: Utilizing the slender and flexible characteristics of optical fibers, it can penetrate into the inner side of the bottle mouth and other narrow spaces to accurately detect minor bottle mouth defects, tiny foreign objects, and extremely thin liquid level foam, never missing any potential quality hazards.

Color sensor: It can accurately distinguish between different colored beverage bottles and the background color of the labels, effectively preventing the problem of mixed packaging;at the same time, it can detect the color consistency of products such as jam and seasonings after filling, ensuring the uniform quality of each batch of products.

Packaging and Labeling: Full-Dimensional Traceability + Dual Safety Assurance

Color Sensor: It can distinguish different colored labels and also identify specific color marking points, providing technical support for precise label positioning, ensuring standardized and beautiful labeling.

Safety door lock: When the equipment is running, it can reliably lock the safety door in the processing area to prevent personnel from entering accidentally and causing safety accidents.

Warehousing and Logistics: Intelligent Sensing Ensures Efficient Flow

Photoelectric sensors: Accurately detect the presence and positioning of pallets and goods, provide real-time feedback on the occupancy status of warehouse storage locations, offer data support for warehouse planning and goods scheduling, and enhance space utilization and turnover efficiency.

Safety barrier: Deployed at key locations such as warehouse entrances and exits, and AGV operation areas, it continuously monitors the proximity of personnel and promptly activates the safety protection mechanism to safeguard the safety of personnel and equipment.

From the farm to the table, every step in the food manufacturing process is crucial to the health of consumers and the reputation of the enterprise.Facing multiple pressures such as cost, safety, efficiency, and manpower, the advanced sensor technology of Dayuan Sensing, like the "nerve endings" embedded in the production process, enables real-time perception, precise control, and intelligent protection.