Today, Wuxi Ruhuan Sensing Technology Co., Ltd. will introduce the Rihuan Sensing RHDF safety photoelectric sensor: Reconstructing industrial safety detection through "time flight".

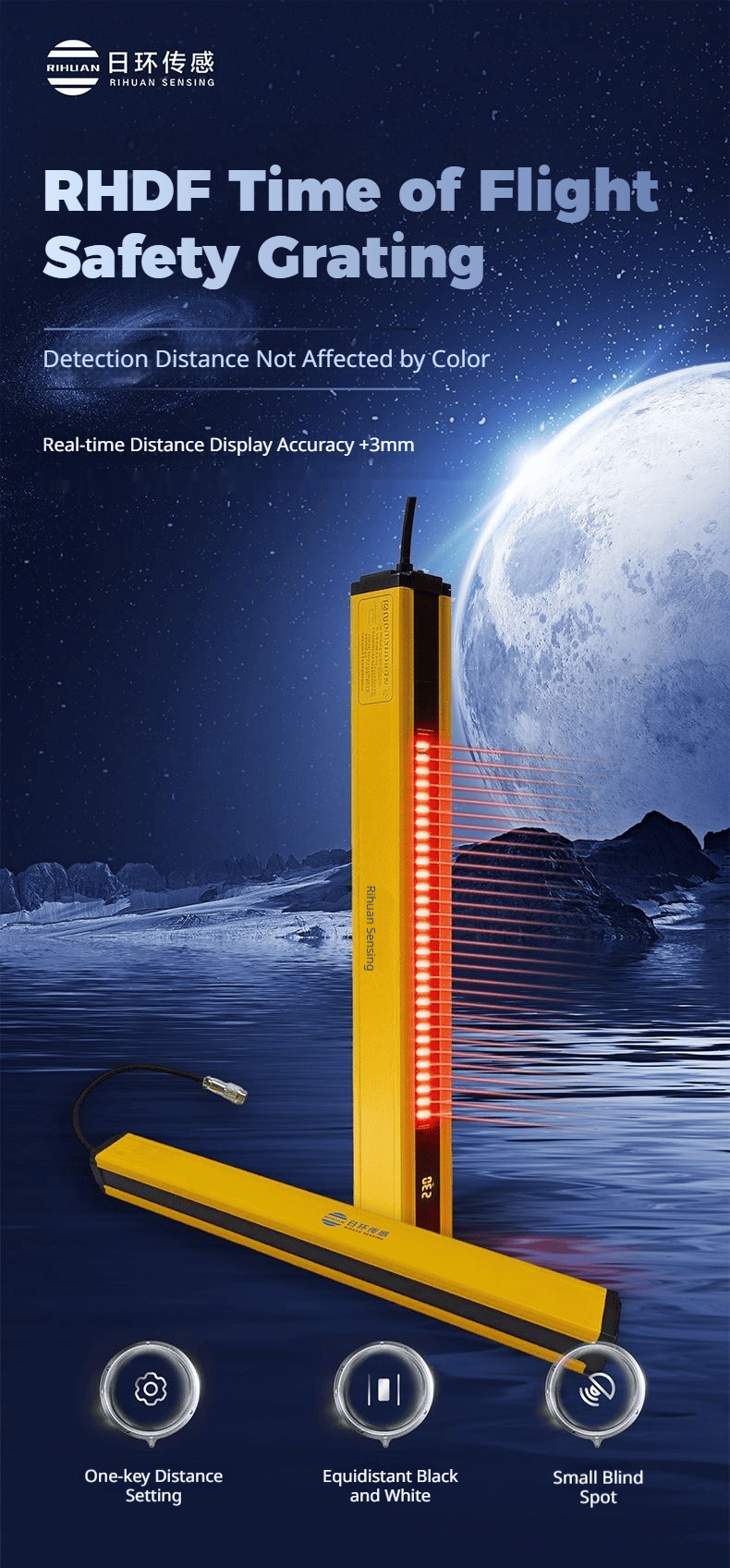

In industrial scenarios, do the "false detections" and "inaccuracies" of safety grilles always cause you headaches? The RHDF time flight safety grilles from Rihuan Sensing have directly addressed these pain points - relying on TOF time flight technology, they have made "color does not affect detection" and "millimeter-level accuracy" standard features.

Key Feature: Solves long-standing industry problems from a fundamental perspective

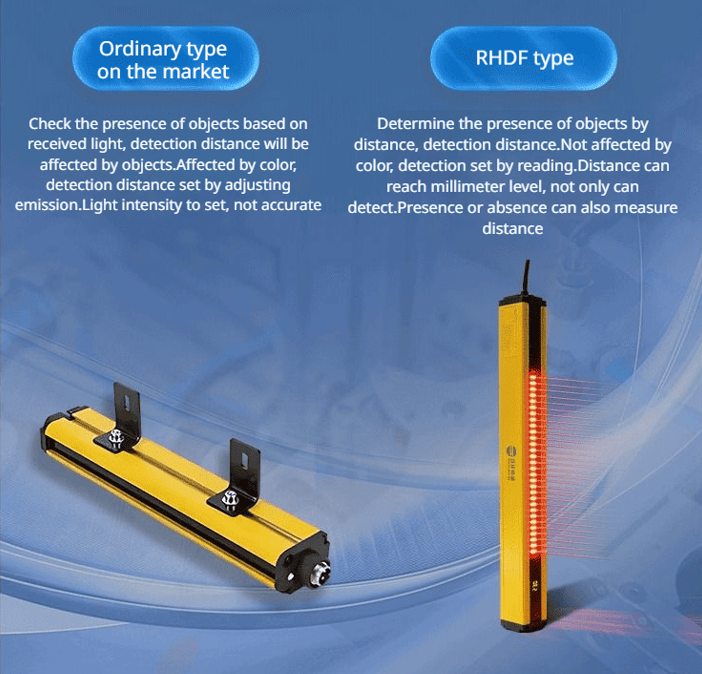

All ordinary safety photoelectric sensors tend to be "biased" by the color of objects? The RHDF type is different:

It calculates the distance by measuring the time difference of light emission. Regardless of whether the detected object is black or white, deep or shallow, it can accurately determine and eliminate "false judgment safety hazards".

The real-time distance display accuracy is ±3mm. It can stably detect both close distances and blind areas. Moreover, it offers the "one-click distance setting" function, significantly reducing the operational effort by half.

Hard power: Not just precise, but also "industrial-grade reliable"

This grating is durable because it is made of high-quality materials:

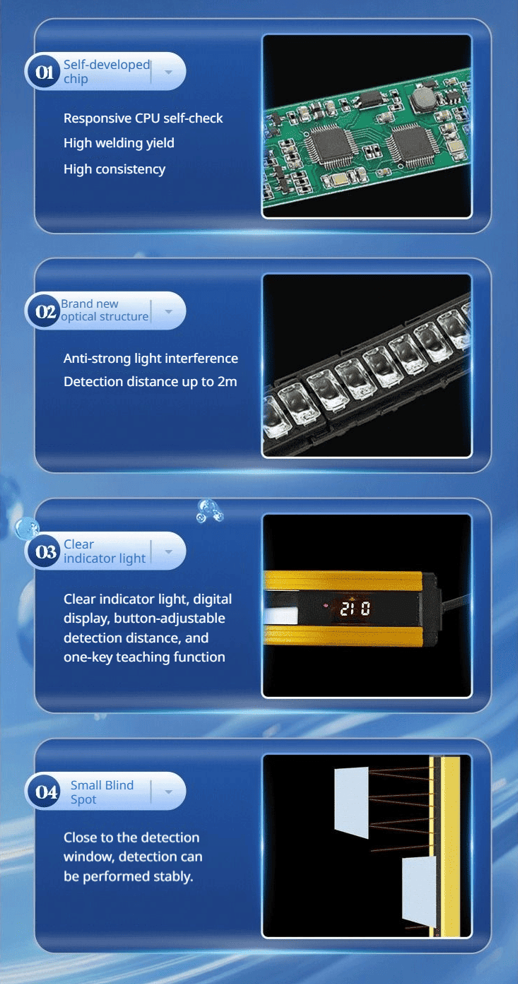

Self-developed chips: Responsive CPU self-checking + high-quality soldering with a high pass rate, ensuring maximum performance consistency;

New optical structure: Resistant to strong light interference, with a maximum detection distance of up to 7 meters. Even in the most complex workshops, it can still perform reliably.

Visual design: The indicator lights and digital display are intuitive and clear. It also features one-click debugging and one-click emergency call functions, eliminating the need to consult the manual during on-site operations.

Area optimization: Both near-range and blind zone detection are reliable. There is no need to add additional protection for "dead zones".

Where? Fully compatible for industrial scenarios

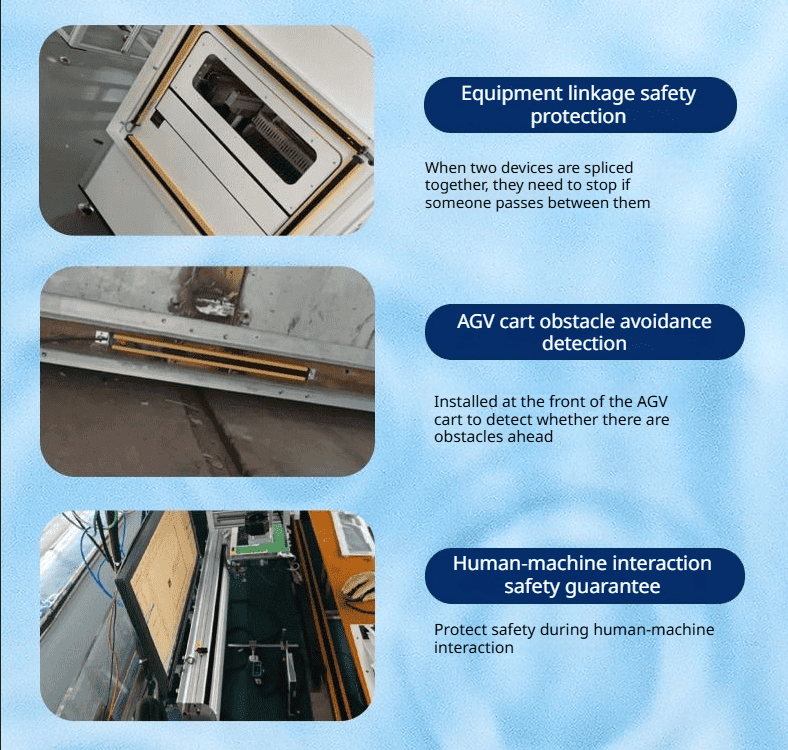

Whether it's equipment interlocking protection (the equipment automatically stops when someone approaches), AGV vehicle obstacle avoidance (identifying obstacles in front in advance), or human-machine interaction safety (real-time protection in the operation area), it can be seamlessly integrated - the technology is not just parameters, but truly capable of addressing the "sense of security" in the actual site.

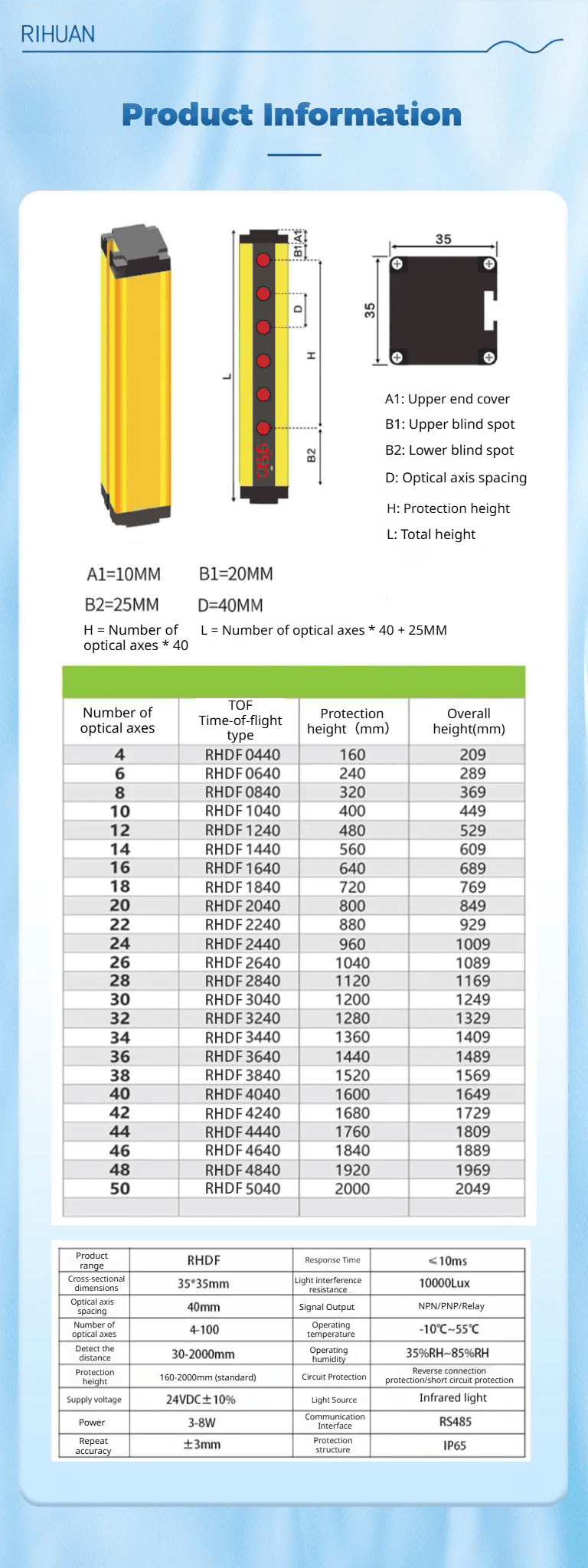

Product parameters are as follows: